Product Description

Hot dip galvanized pipe is made of molten metal and iron matrix reaction to produce alloy layer, so that the matrix and coating two combination. Hot dip galvanizing is to first pickling the steel tube. In order to remove the iron oxide on the surface of the steel tube, after pickling, it is cleaned in the tank of ammonium chloride or zinc chloride solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel tube base and the molten bath to form a compact zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the steel tube matrix. Therefore, its corrosion resistance is strong.

Grade:

DX51D+Z、DX52D+Z、DX53D+Z、DX54D+Z、DX56D+Z

Size:

Diameter: 0.6mm to 8mm

Roll Weight: 20kg to 1 tons

Standard:

GB/T3091-2001, BS 1387-1985, DIN EN10025, EN10219, JIS G3444:2004, ASTM A53 SCH40/80/STD, BS- EN10255- 2004

Packing:

SSeaworthy Package

Parameters

|

Product Name

|

Galvanized Wire

|

|

Package

|

5kgs/roll, pp film inside and hassian cloth outside or pp woven bag outside

|

|

25kgs/roll, pp film inside and hassian cloth outside or pp woven bag outside

|

|

|

50kgs/roll, pp film inside and hassian cloth outside or pp woven bag outside

|

|

|

Material

|

Q195/Q235

|

|

Production QTY

|

1000tons/Month

|

|

MOQ

|

5 tons

|

|

Application

|

Binding wire

|

|

Payment term

|

T/T, L/C or Western Union

|

|

Delivery time

|

about3-15 days after pre-payment

|

|

Wire Gauge

|

SWG(mm)

|

BWG(mm)

|

Metric(mm)

|

|

8

|

4.05

|

4.19

|

4

|

|

9

|

3.66

|

3.76

|

4

|

|

10

|

3.25

|

3.4

|

3.5

|

|

11

|

2.95

|

3.05

|

3

|

|

12

|

2.64

|

2.77

|

2.8

|

|

13

|

2.34

|

2.41

|

2.5

|

|

14

|

2.03

|

2.11

|

2.5

|

|

15

|

1.83

|

1.83

|

1.8

|

|

16

|

1.63

|

1.65

|

1.65

|

|

17

|

1.42

|

1.47

|

1.4

|

|

18

|

1.22

|

1.25

|

1.2

|

|

19

|

1.02

|

1.07

|

1

|

|

20

|

0.91

|

0.84

|

0.9

|

|

21

|

0.81

|

0.81

|

0.8

|

|

22

|

0.71

|

0.71

|

0.7

|

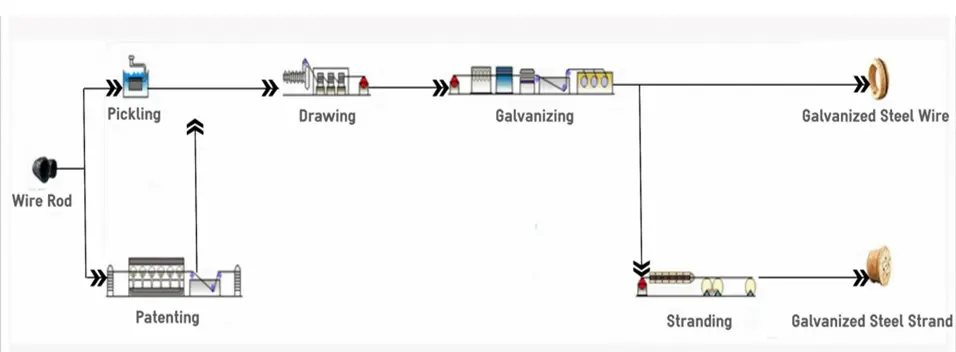

Production Process

The production of galvanized steel wire firstly adopts the raw material carbon steel wire through the plate element peeling, pickling, washing, saponification, drying, drawing, annealing, cooling, pickling, washing, galvanized line, packaging and other procedures.

Features

1) Galvanized Steel Wire is widely used in construction, handicrafts, preparation of wire mesh, production of galvanized hook mesh, daub mesh, highway guardrail, product packaging and daily civilian and other fields.

In the communication system, galvanized steel wire is suitable for transmission lines such as telegraph, telephone, cable broadcasting and signal transmission.

In the power system, because the zinc layer of the steel wire is relatively large, thick and has good corrosion resistance, it can be used for the armoring of cables with severe line corrosion.

2) ROYAL GROUP Galvanized Steel Wire, which with Highest quality and strong supply ability are widely used in Steel structure and Construction.

DETAILS SHOW

Diameter

Steel wire diameter can be produced from 0.6mm to 8mm, hot – dip galvanized, electro – galvanized and pre – galvanized are available.

Coil Weight & Guaranteed Quality

Can be produced according to customer needs, 20kg – 1ton, the most demanded by customers is 500kg rolls.

Weights are all within reasonable tolerances.

Applications

Our galvanized, galvalume and pre-painted steel products are widely used across various industries, including but not limited to:

📦 Packaging & Transportation

✅ Packaging Details

- Waterproof plastic film for moisture & rust protection

- Kraft paper or galvanized wrapping

- Edge protection with metal corners or rubber pads

- Secured with steel straps (inner & outer)

- Wooden or steel pallets available

🚚 Transportation Options

- Full container or bulk shipping (FOB / CIF / CFR)

- Truck transport to port or designated warehouse

- Palletized LCL shipping available for small orders

- Complete shipping documents provided (Packing List, Invoice, CO, etc.)