PRODUCTION TECHNOLOGY

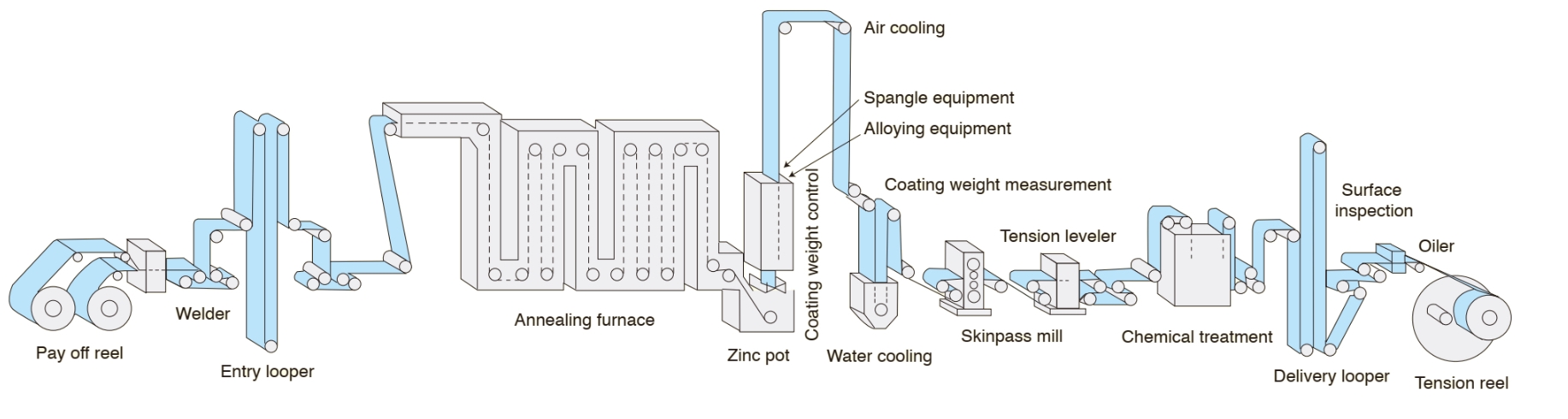

The typical production process of cold-rolled steel strip hot-dip galvanizing is:

Loading → uncoiling → pinch, straightening → welding → surface pre-cleaning → inlet looper → annealing → hot-dip galvanizing → alloying → cooling → middle looper → smoothing → stretching and bending straightening → post-processing → inspection Take-up.

Continuous annealing furnace shell:

Generally, ceramic fiber outsourcing stainless steel plates are used, refractory bricks and heat-insulating bricks are used for the furnace bottom, and the furnace rolls are driven separately and frequency-converted. Generally, the annealing furnace is composed of a preheating section, a heating section, a cooling section, and a zinc pot inlet section. In the first three sections, a mixed gas of hydrogen and nitrogen is introduced to heat the strip steel to above the recrystallization temperature in this reducing atmosphere, and Heat preservation, soaking, and cooling make the strip steel sealed into the zinc pot for hot-dip galvanizing.

There are two main purposes: one is to achieve recrystallization annealing of the strip to eliminate rolling stress, restore the grain structure, and improve the plasticity of the strip; the second is to make the steel have a clean and oxide-free active surface, so that it has a very High plating adhesion.

| S/N | Content | S/N | Content |

|

01

|

Unbook | 08 | Zinc pot |

| 02 | Straighten | 09 | Zinc layer annealing furnace |

| 03 | Cut | 10 | Air knife |

| 04 |

Welding

|

11 |

Smooth

|

| 05 | Preheating section | 12 | Stretch straightening |

| 06 | Heating section | 13 | Chemical treatment |

| 07 | Cooling section | 14 | Take-up |

POST PROCESSING

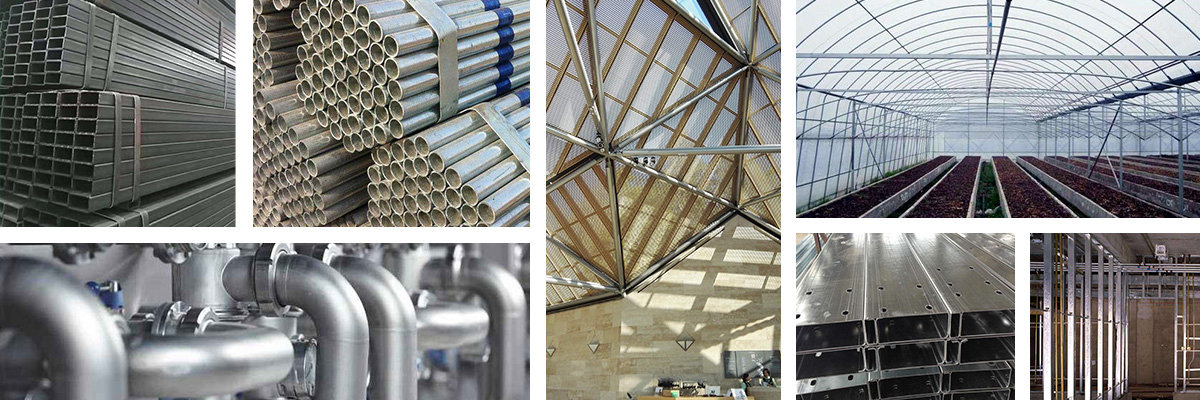

PRODUCT USE

Galvanized steel strip is generally used to make steel pipes, such as greenhouse pipes, drinking water pipes, heating pipes, gas delivery pipes; it can also be used in construction, light industry, automobiles, agriculture, animal husbandry, fishery, and commerce.

Among them, the construction industry is mainly used to manufacture anti-corrosion industrial and civil building roof panels, roof grills, etc.; the light industry uses it to manufacture household appliance shells, civil chimneys, kitchen appliances, etc., and the automobile industry is mainly used to manufacture corrosion-resistant parts for cars. ;Agriculture, animal husbandry and fishery are mainly used as food storage and transportation, meat and aquatic products frozen processing tools, etc.; commercial mainly used as material storage and transportation, packaging tools; steel structure sandalwood (C, Z steel); light steel keel, suspended ceiling Keel and so on.

Applications

Our galvanized, galvalume and pre-painted steel products are widely used across various industries, including but not limited to:

📦 Packaging & Transportation

✅ Packaging Details

- Waterproof plastic film for moisture & rust protection

- Kraft paper or galvanized wrapping

- Edge protection with metal corners or rubber pads

- Secured with steel straps (inner & outer)

- Wooden or steel pallets available

🚚 Transportation Options

- Full container or bulk shipping (FOB / CIF / CFR)

- Truck transport to port or designated warehouse

- Palletized LCL shipping available for small orders

- Complete shipping documents provided (Packing List, Invoice, CO, etc.)