Product Description

Hot dip galvanized pipe is made of molten metal and iron matrix reaction to produce alloy layer, so that the matrix and coating two combination. Hot dip galvanizing is to first pickling the steel tube. In order to remove the iron oxide on the surface of the steel tube, after pickling, it is cleaned in the tank of ammonium chloride or zinc chloride solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the steel tube base and the molten bath to form a compact zinc-iron alloy layer with corrosion resistance. The alloy layer is integrated with the pure zinc layer and the steel tube matrix. Therefore, its corrosion resistance is strong.

Parameters

|

oduct Name

|

Galvanized Steel Round Pipe (Hot Dipped or Pre Galvanized)

|

|

Material

|

Q195 Q235 Q345

|

|

Wall Thickness

|

1MM~12MM as the requirement

|

|

Outer Diameter

|

21.3MM~219.1MM

|

|

Length

|

5m-14m,5.8m,6m,10m-12m,12m or as customer’s actual reques

|

|

Zinc Coating

|

30g-275g

|

|

Technique

|

ERW(GALVANIZED)

|

|

Packing

|

Bundle, or with all kinds of colors PVC or as your requirements

|

|

Pipe Ends

|

Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc.

|

|

Surface Treatment |

1. Galvanized2. PVC,Black and color painting3. Transparent oil,anti-rust oil

4. According to clients requirement |

|

Product Application

|

1. Fence, greenhouse, door pipe,greenhouse2. Low pressure liquid, water, gas, oil, line pipe3. For both indoor and outdoor the building construction

4. Widely used in scaffolding construction which is much cheaper and convenient |

|

Origin

|

Tianjin China

|

Production Process

Features

1. Corrosion resistance: Galvanizing is an economic and effective rust prevention method that is often used. About half of the world’s zinc output is used in this process. Not only does zinc form a dense protective layer on the steel surface, but it also has a cathodic protection effect. When the zinc coating is damaged, it can still prevent the corrosion of the iron base material by cathodic protection.

2. Good cold bending and welding performance: mainly used low carbon steel grade, the requirements have good cold bending and welding performance, as well as a certain stamping performance

3. Reflectivity: It has high reflectivity, making it a barrier against heat

4, the coating toughness is strong, galvanized layer forms a special metallurgical structure, this structure can withstand mechanical damage in transport and use.

DETAILS SHOW

Standard length 6mts or 12 mts

Cutting length from 6 – 12meters,we can provide American standard length 20ft 40ft.

Or we can open mold to customize product length,such as 13 meter ect.

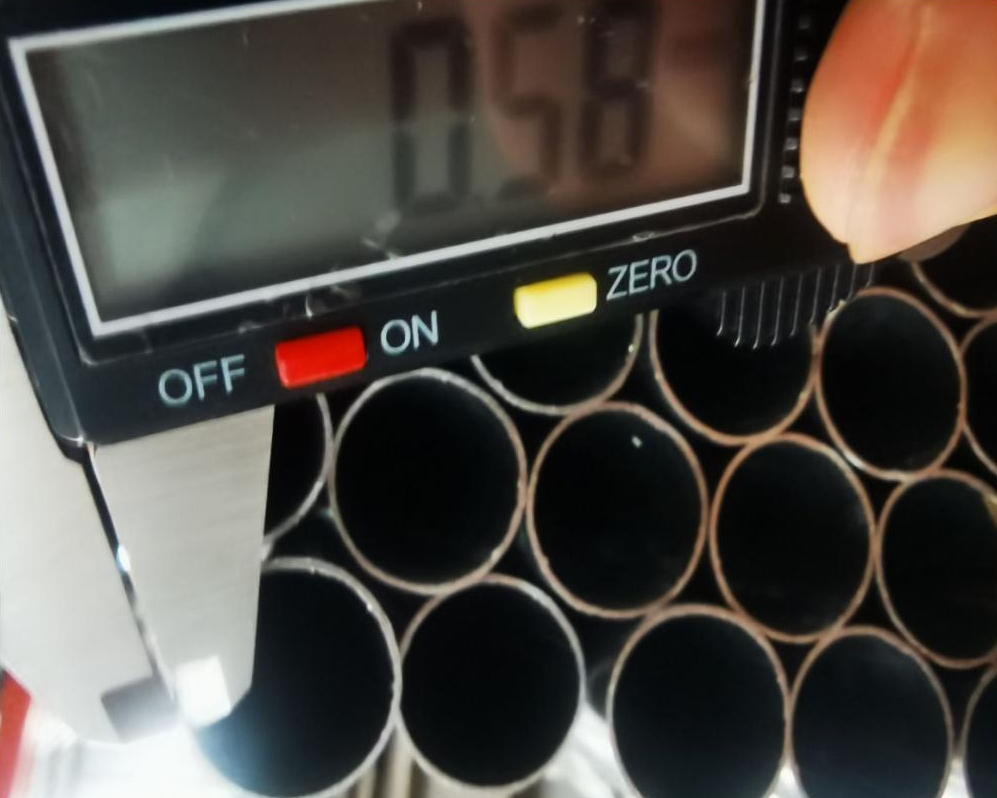

Standard Thickness &Guaranteed Quality

The thickness is produced in accordance with the contract.

Our company process the thickness tolerance is within ±0.01mm.

Nozzle Level & Weld Neat

Laser cutting nozzle,the nozzle is smooth and neat.

Straight seam welded pipe,galvanized surface.

Enough Zinc Coating

Zinc layers can be produced from 30g to 550g and can be supplied with hot dip galvanizing, electric galvanizing and pre – galvanizing.

Provides a layer of zinc production support after inspection report.

Applications

Our galvanized, galvalume and pre-painted steel products are widely used across various industries, including but not limited to:

📦 Packaging & Transportation

✅ Packaging Details

- Waterproof plastic film for moisture & rust protection

- Kraft paper or galvanized wrapping

- Edge protection with metal corners or rubber pads

- Secured with steel straps (inner & outer)

- Wooden or steel pallets available

🚚 Transportation Options

- Full container or bulk shipping (FOB / CIF / CFR)

- Truck transport to port or designated warehouse

- Palletized LCL shipping available for small orders

- Complete shipping documents provided (Packing List, Invoice, CO, etc.)